WE PROVIDE ONE-STOP SERVICES

ALL OVER THE WORLD.

▶ position:

Zhongshan Mayen Commerce and Trading Co., Ltd. is one of the highly reputed laboratory products suppliers. We have specialized in the development and designing of epoxy resin worktops and sinks, facilitating our customers all over the world with optional solutions under full coverage of safety, sustainability and affordability.

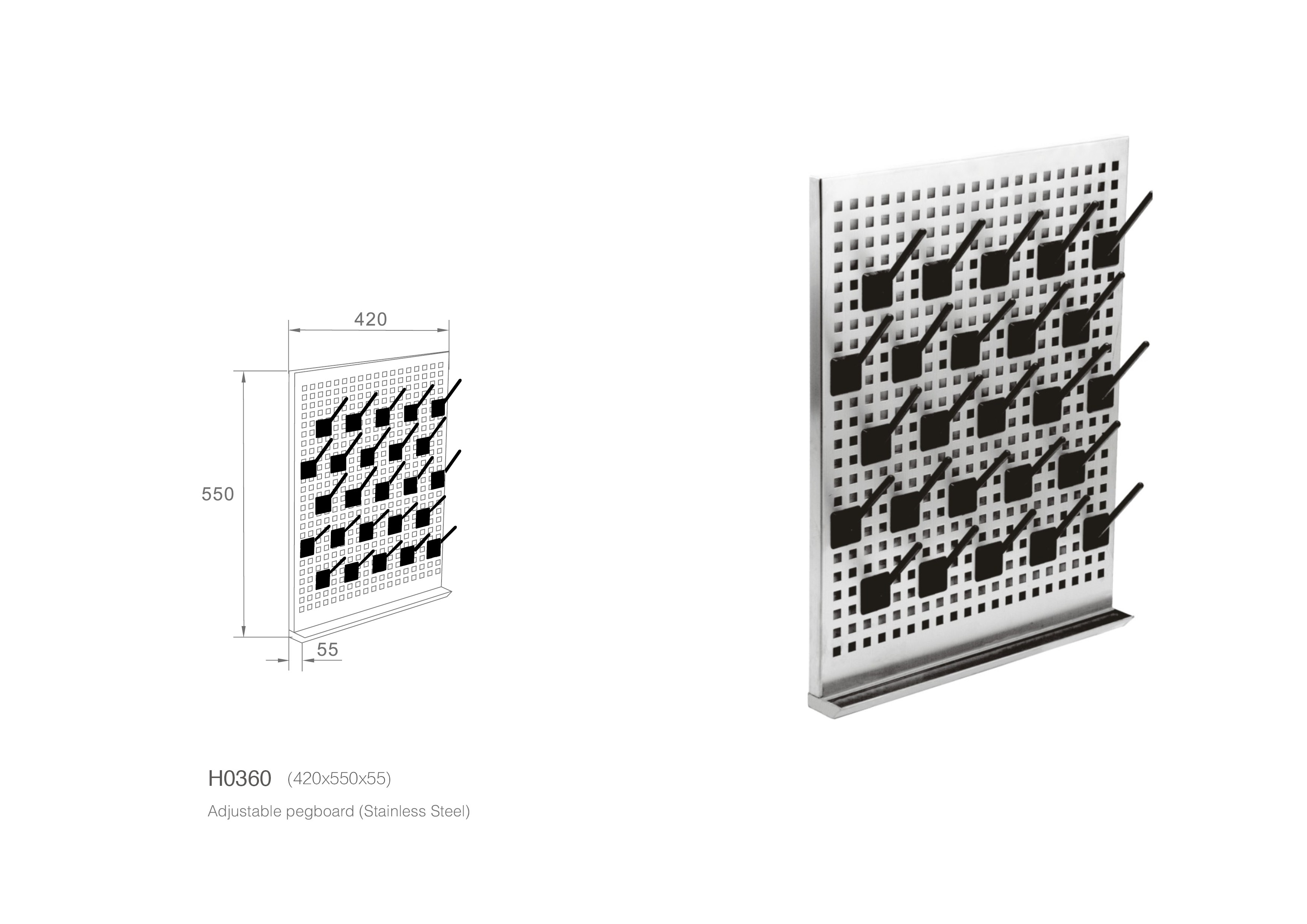

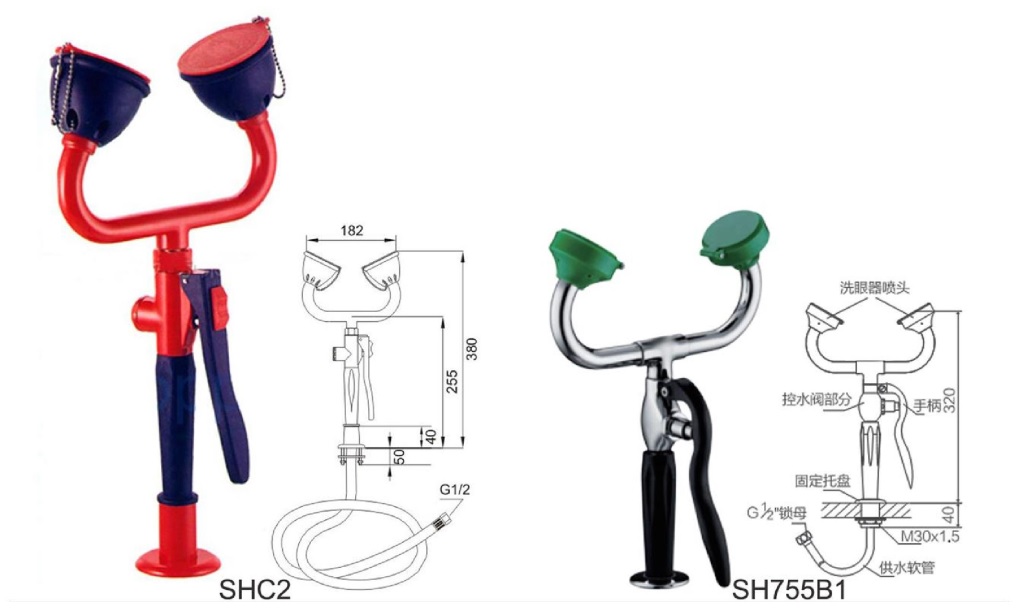

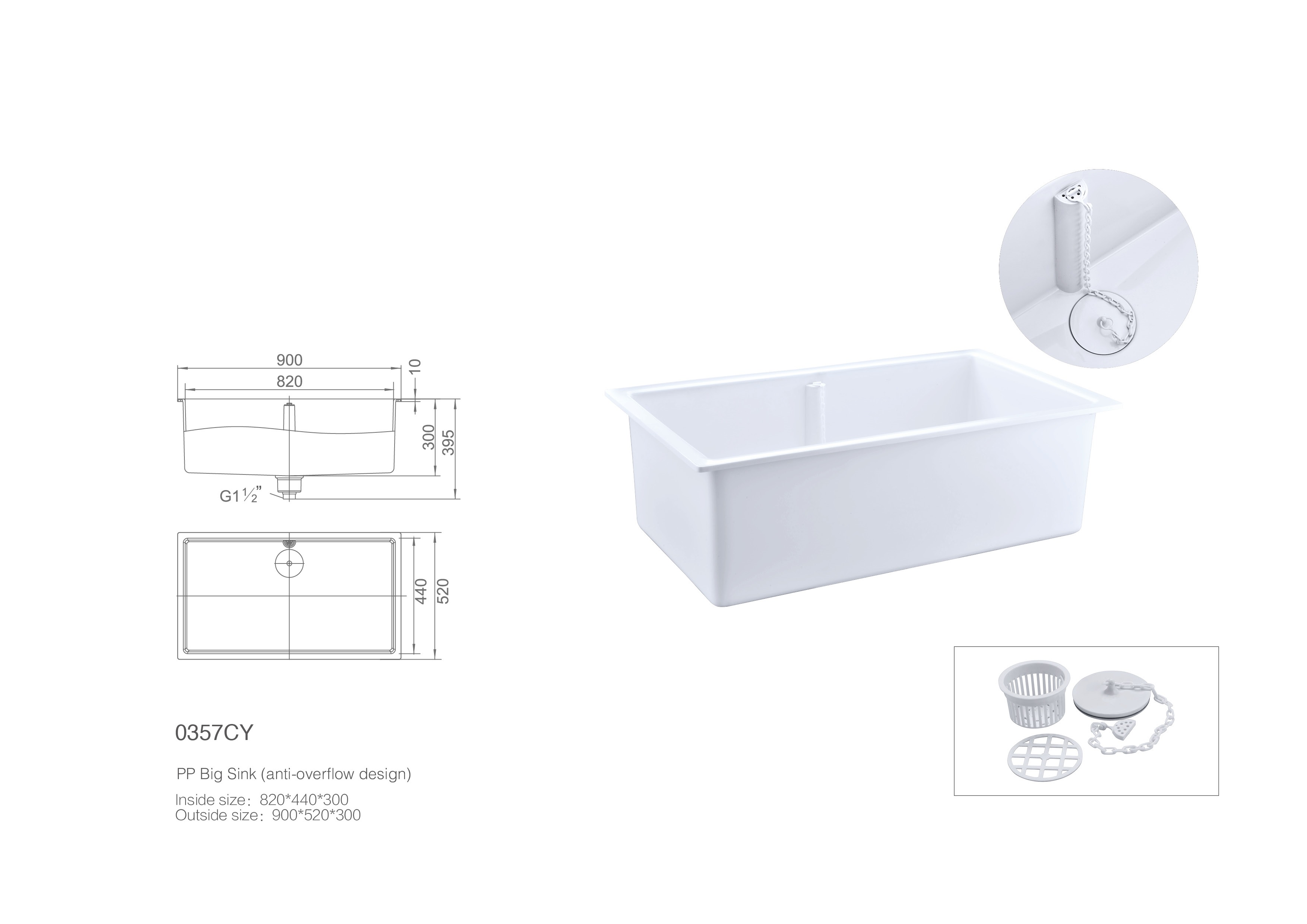

Our products including epoxy resin worktops, epoxy resin sinks, phenolic worktops, water faucets, gas fittings, emergency showers, eye washes, pegboards, extraction arms and other accessories, fume hoods, equipment and lab furniture for laboratory, are are designed to meet the demands of the industrial, educational, healthcare and pharmaceutical sectors.

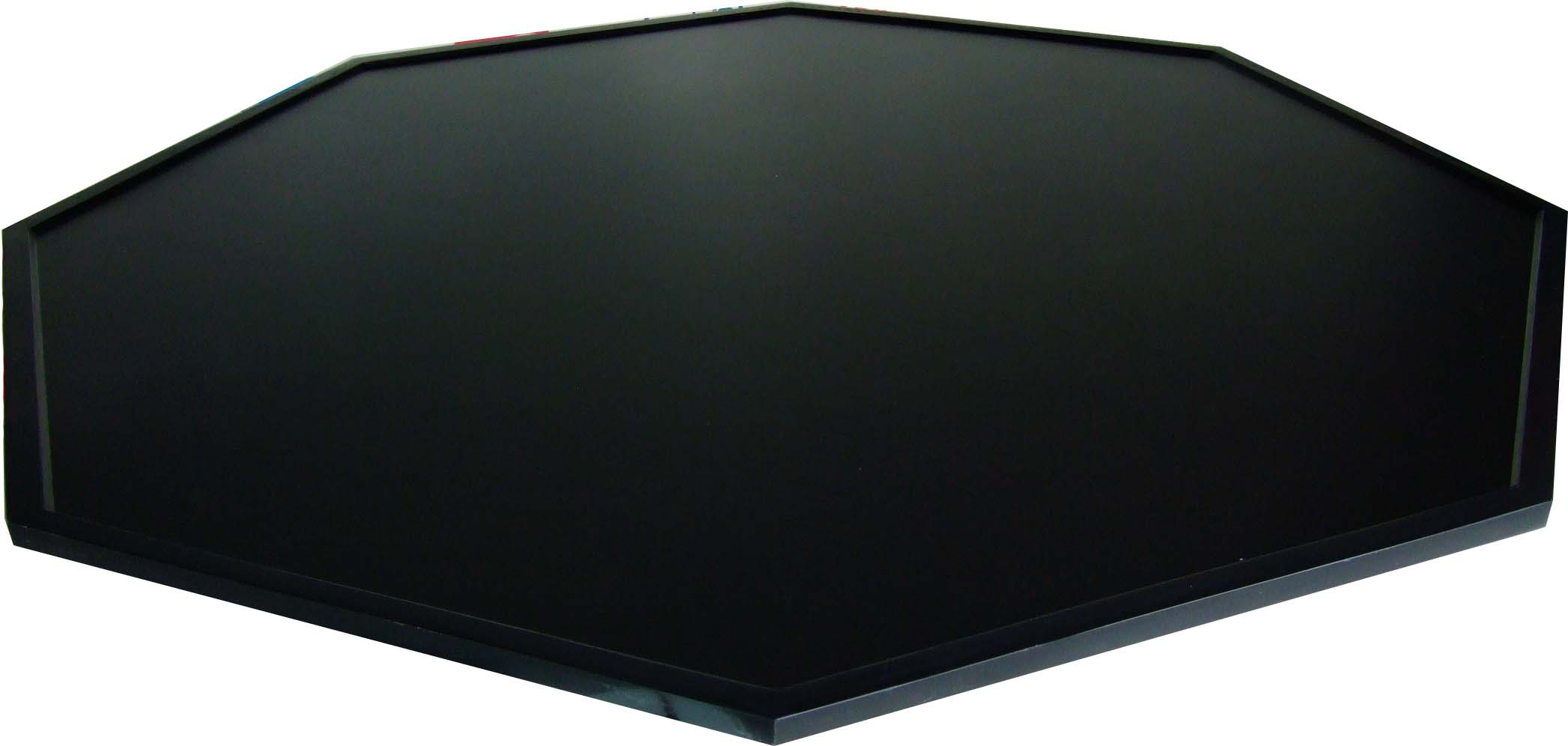

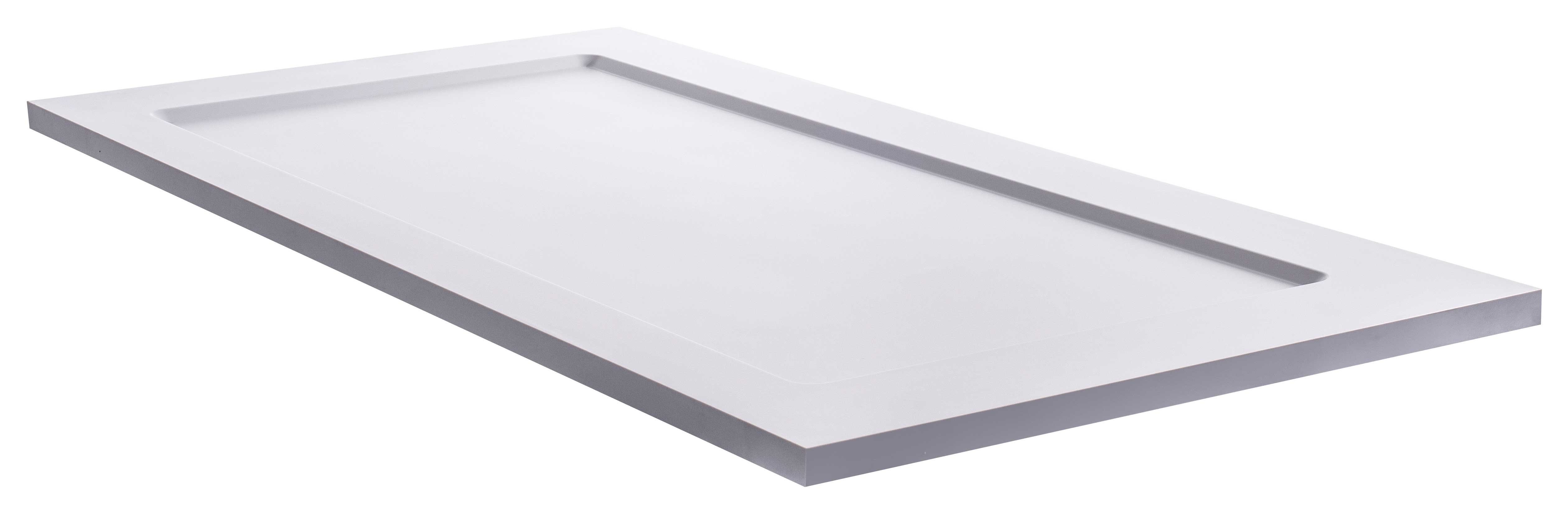

Mayen’s New Generation epoxy resin worktop adopts the newly developed epoxy resin system, the new production process and the fully automated production process technology. This integrated core epoxy resin worktop is patented, processed by multi-process and high temperature compounding. This matte finish surface epoxy resin worktop is processed by more than 40 fully automated polishing equipment, so it has uniform thickness.

Mayen’s New Generation epoxy resin worktop retains the chemical stability, heat resistance and mechanical properties of the traditional epoxy resin worktop. It is of superior corrosion resistance, excellent high temperature resistance, durable reducibility, environmental safety.

Mayen’s New Generation epoxy resin worktop strengthens the surface hardness of the product and enhances the mechanical strength and increases the scratch resistance. It improves the production capacity perfectly and increases the molding area of the product. The single piece can be molded into 3000mmx1600mm, which can meet the design and installation of super large laboratory worktop for the projects.

3000mm x 1600mm

-Please contact us for the cutting sheets.

Thickness:

15mm

19mm

25mm

Cutting sheets:

Square

Round

Octagon/Hexagon

Sink module units

- Please contact us for other customized shapes.

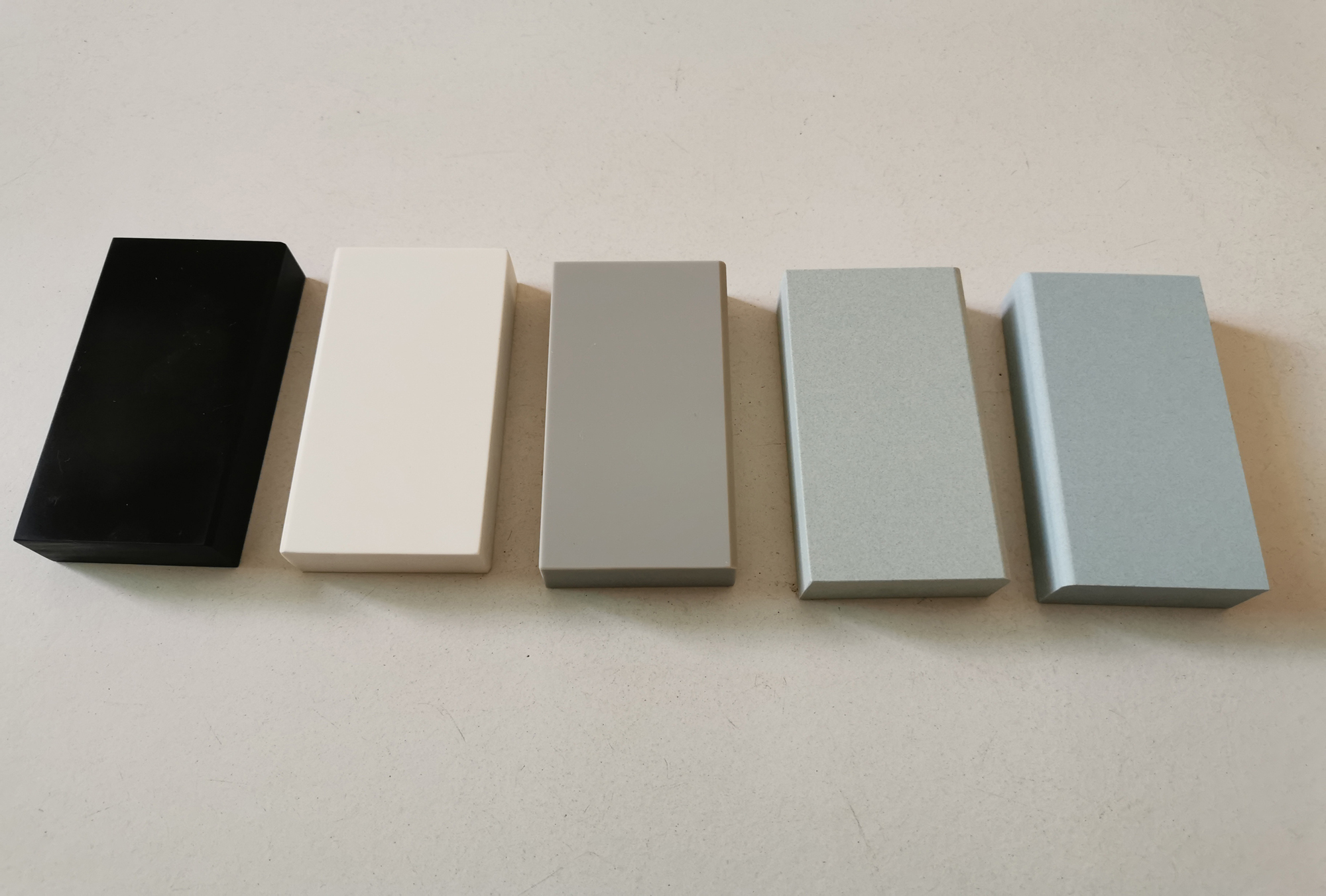

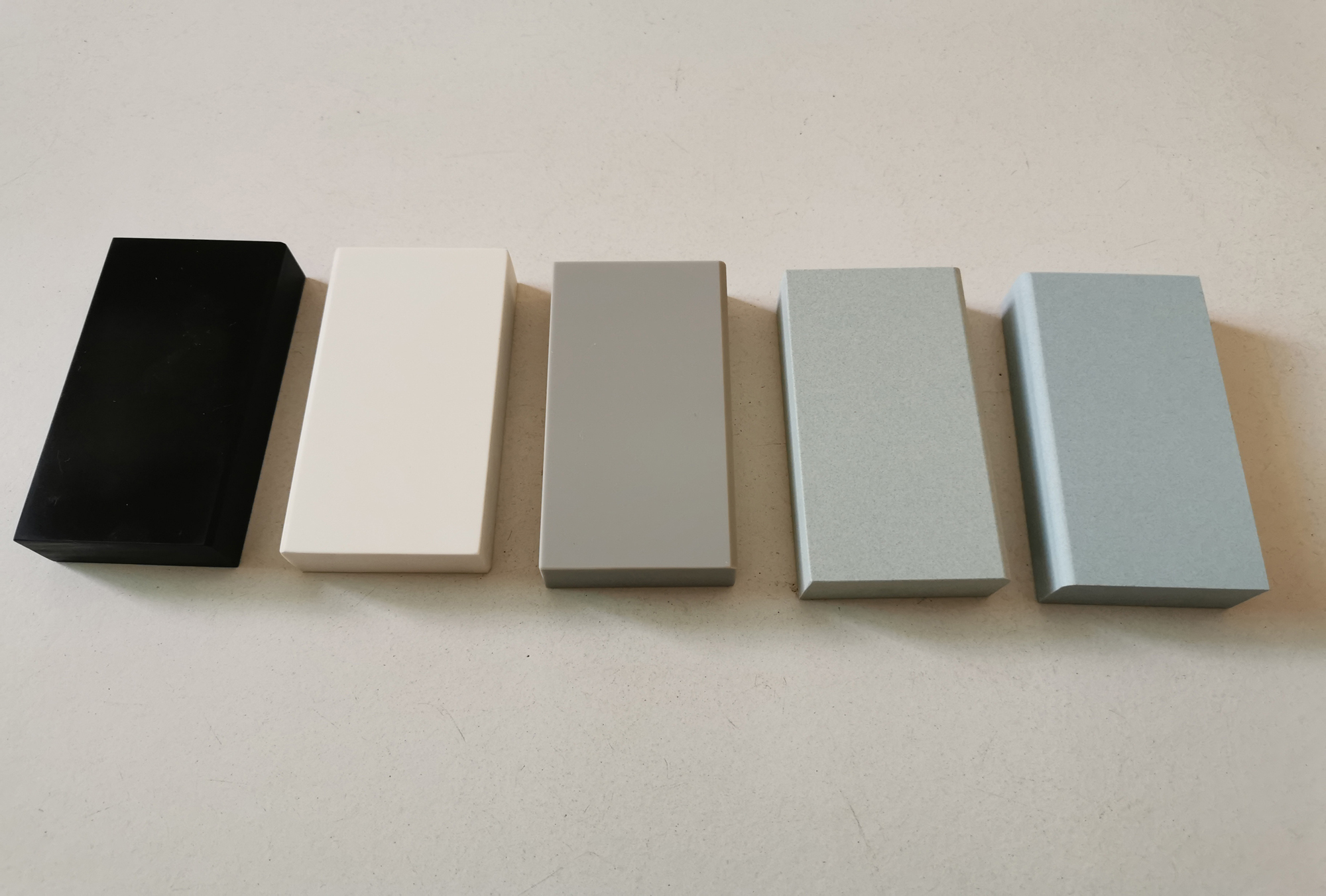

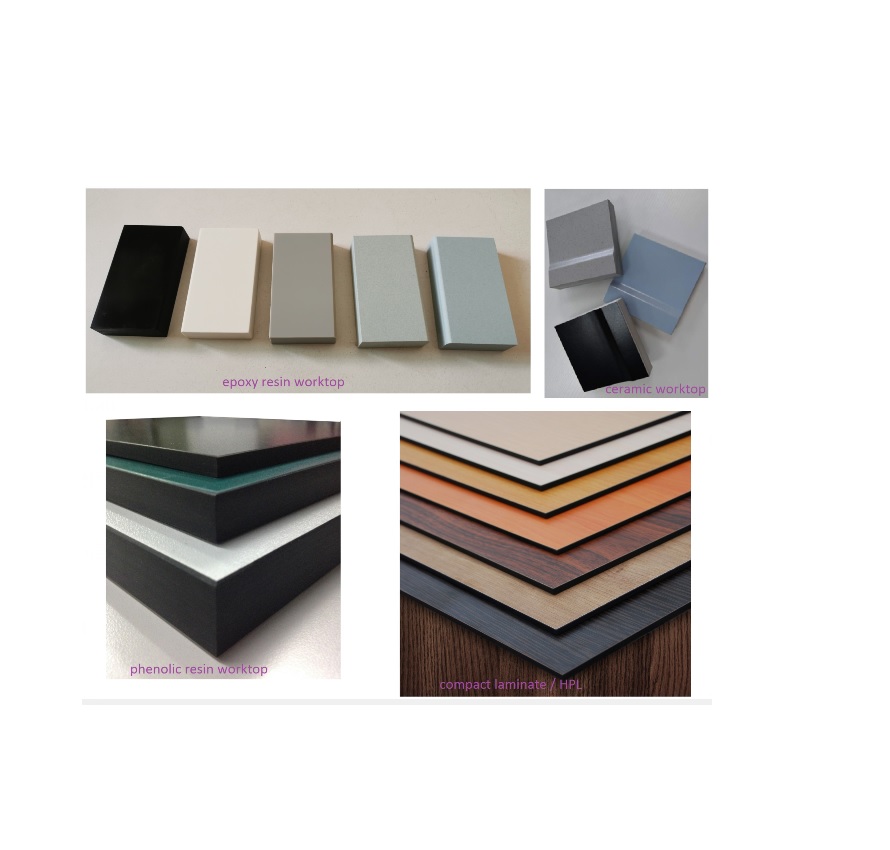

Colors:

Black | |

White | |

Dark grey Grey Ice blue | |

| |

- Please contact us for other colors.

| |

ADVANTAGES OF MAYEN EPOXY RESIN WORKTOPS

DURABILITY

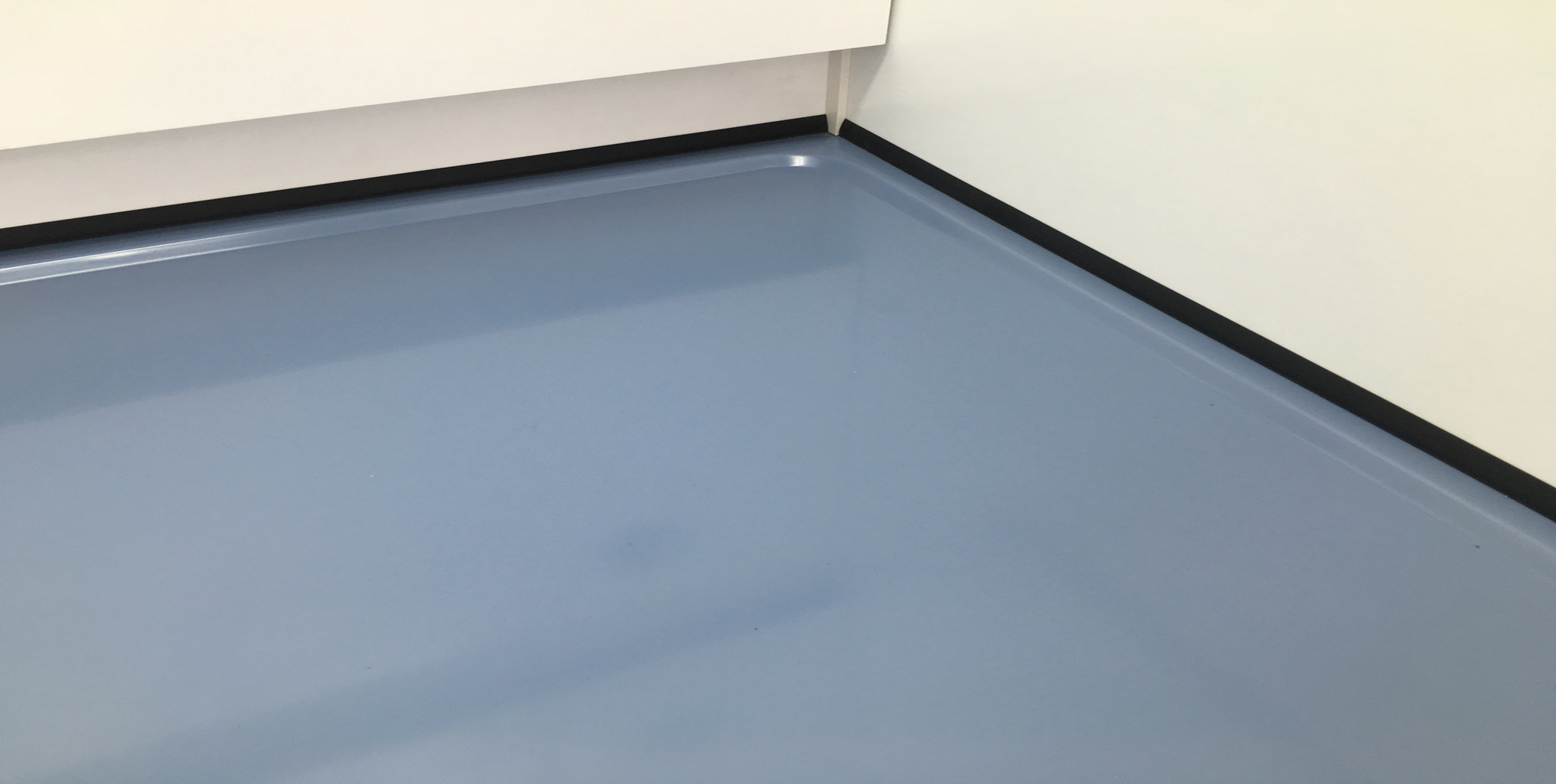

MAYEN epoxy resin worktops are monolithic and non-porous; they do not delaminate or swell. They are easy to install on site.

APPEARANCE

MAYEN epoxy resin worktops have a smooth and matte surface that is easy to clean and maintain.

CHEMICAL RESISTANCE

MAYEN epoxy resin worktops are highly resistant to the corrosive effects of most chemicals and organic solvents and compounds.

HEAT RESISTANCE

MAYEN epoxy resin worktops will not blister or crack when exposed to extreme temperatures in the laboratory.

SAFETY

MAYEN epoxy resin worktops are enhanced by a natural, asbestos-free additive, providing fire resistance and insulation properties in a user-safe environment.

INDOOR AIR QUALITY

MAYEN epoxy resin worktops are low-emission certified.

CHEMICAL RESISTANT PROPERTIES TESTING

Method A

Used for Volatile Chemicals (organic solvent):

A cotton ball, saturated with the test chemical (reagent), is placed in a 1-ounce test tube with a reservoir of liquid above the ball. The container is inverted on the test material at a standard temperature of 23℃ plus or minus 2℃ (73°plus or minus 4℉).

Method B

Used for Non-Volatile Chemicals:

5 drops (1/4cc) of the test chemical are placed on the test material surface. The chemical is covered with a watch glass (d=125px) at a standard temperature of 23°plus or minus 2℃ (73°plus or minus 4℉).

For both the above methods (A and B), leave the reagents on the panel for a period of: 1 hour for exposed vertical surfaces and semi-exposed surfaces, 24 hours for exposed horizontal surfaces such as countertops. After exposure, exposed areas are washed with water, then a detergent solution, finally with naphtha, then rinsed with distilled water and dried with a cloth.

Chemicals | Concentration | Method | Test Result | |

Inorganic Acids - Corrosive | ||||

Chromic Acid (CrO3) | 40% | B | 1 | |

Hydrochloric Acid (HCL) | 10% | B | 1 | |

Hydrochloric Acid (HCL) | 37% | B | 1 | |

Nitric Acid (HNO3) | 40% | B | 1 | |

Nitric Acid (HNO3) | 70% | B | 1 | |

Sulfuric Acid (H2SO4) | 40% | B | 1 | |

Sulfuric Acid (H2SO4) | 96% | B | 3 | |

Hydrofluoric Acid (HF) | 48% | B | 3 | |

Organic Acids - Corrosive | |||

Acetic Acid (CH3CO2H) | 5% | B | 1 |

Acetic Acid (CH3CO2H) - Glacial | 99% | B | 1 |

Citric Acid (C6H8O7) | 1% | B | 1 |

Oleic Acid (C18H34O2) | Original | B | 1 |

Phenol Solution (C6H5OH) | 5% | B | 1 |

Alkaline Solutions - Corrosive | |||

Ammonium Hydroxide (NH4OH) | 10% | B | 1 |

Potassium Hydroxide(KOH) | 15% | B | 1 |

Sodium Carbonate Sol (Na2CO3) | 20% | B | 1 |

Sodium Hydroxide Sol (NaOH) | 60% | B | 1 |

Sodium Hypochlorite Sol (NaOCI) | 4% | B | 1 |

Organic Solvents | |||

Acetone (CH3COCH3) | Original | A | 2 |

Benzene (C6H6) | Original | A | 2 |

Carbon Tetrachloride (CCI4) | Original | A | 1 |

Diethyl Ether (CH3CH2OCH2CH3) | Original | A | 1 |

Dimethyl Formamide (HCON[CH3]2) | Original | A | 1 |

Ethyl Acetate (CH3CO2C2H5) | Original | A | 2 |

Ethyl Alcohol (CH3CH2OH) | Original | A | 1 |

Etheylene Dichloride (CICH2CHCI) | Original | A | 1 |

Heptane (CH3[CH2]5CH3) | Original | A | 1 |

Isooctane (C8H18) | Original | A | 1 |

Kerosene | Original | A | 1 |

Methyl Alcohol (CH3OH) | Original | A | 1 |

Organic Compounds | |||

Aniline (C6H5NH3) | Original | B | 2 |

Mineral Oil | Original | B | 1 |

Olive Oil | Original | B | 1 |

Soap Solution | 1% | B | 1 |

Transformer Oil | Original | B | 1 |

Turpentine | Original | B | 2 |

The effect on the surface of the specimen is inspected visually and express in accordance with the following rating scale:

09042019

PHYSICAL PROPERTIES TESTING

Physical Properties | Test Standard | Tested Data |

1a. Specific Gravity, average | ASTM D792 : 2000 | 2.24 |

1b. Density (g/cm³), average | 2.24 | |

2. Rockwell Hardness (M Scale), average | ASTM D785 : 2003 | 125 |

3. Heat Deflection Temperature (℃), average | ASTM D648 : 2007 | 243 ℃ |

4a. % Water Absorbed, average | ASTM D570 : 1998(2005) ASTM D570 : 1998(2005) | 0.010 |

4b. % Increase in Weight, average | 0.010 | |

4c. % Soluble Matter Loss, average | None | |

5. Flammability (Horizontal) | ASTM D635 : 2003 | Not flammable |

ASTM D695 : 2002 ASTM D638 : 2003 | 211.9 | |

7a. Maximum Tensile Strength (Mpa), average | 58 | |

7b. Tensile Modulus (Mpa), average | 12618 | |

8a. Flexural Strength (Mpa), average | ASTM D790 : 2003 | 98.7 |

8b. Flexural Modulus (Mpa), average | 10929 |

MAINTENANCE AND REPAIR

MAYEN epoxy resin worktops will not stain and are resistant to most abrasive chemicals. Periodic cleaning with a 70% ethyl alcohol solution is recommended (other waxes or coatings should not be applied). MAYEN epoxy resin worktops can suffer damage however through abuse or neglect. Scratches and marks can usually be repared on site using the following materials and procedure:

Material required:

• Oil (mineral or light machine oil)

• Silicone Carbide Sandpaper (grits 80, 120 and 220)

• 3M Scotch Brite (or equivalent)

• Clean cloths

Depending on field conditions, either hand-tools or power-tools may be used to repair scratches.

Procedure:

1. Apply oil to the area to be repaired, then begin sanding with 80 grit sandpaper in the same direction as the scratch using a moderate to light touch until scratch disappears. The lighter the pressure, the less material is removed, and the better the repair will look.

2. The final sanding should be done using 220 grit paper and oil. Again, work in the same direction as the scratch using a light touch. Use plenty of oil to remove sanding marks from the work surface. Buff the sanded area with oil and 3M Scotch Brite until you are satisfied with the result. Buff further with clear rags and the repair is complete.

Zhongshan Mayen Commerce and Trading Co., Ltd.

Add.: Plant No. 3, B2, Floor 2, No. 23, Jinhong Road, Pingnan Village, Sanxiang Town, Zhongshan City, Guangdong, China 528463

Tel.: & Fax.: 0086-760-86697366

Website: www.mayencn.com

E-mail: sales3@mayencn.com / mayencn4@hotmail.com

Mobile: 0086-13928185615 (WeChat / WhatsApp)

Copyright (c)2018-2022 Zhongshan Mayen Commerce and Trading Co., Ltd. All Rights Reserved Website management

.jpg)